Prepainted Steel Coil/Sheet Introduction:

-

Dimensions:

The width range of supplied prepainted steel sheet for ANSON steel is 700-1550mm; The thickness range of the design is 0.2-2.0 mm, which can provide the steel volume of 508 or 610mm inner diameter.

-

Steel Grade:

ANSON steel supplies steel grades of color coating products have high strength steel color, deep steel color coating, general molding used for color painting, and other advanced high-strength steel paints, such as double - phase steel or polyphase steel, which can improve the anti-wind ability.

-

Substrate Plate Type:

The base plate of ANSON steel color coated steel plate includes hot galvanizing, electro-galvanizing, aluminized zinc and other basic plates, as well as newly developed zinc-alumina magnesium base plate. The coating weight not only has the double thickness coating, but also has two different thickness coating.

-

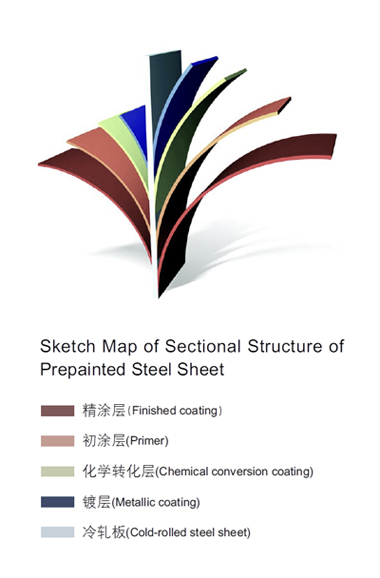

Coated Layer Structure:

The coated products of ANSON steel are 2/2, 2/1, 1/1, 3/2, 2/1M, etc.

-

Coating Types:

ANSON steel color coating products include polyester (PE), fluorocarbon (PVDF) color coating, silicon modified polyester (SMP) color coating, high tolerance (HDP) and other paint varieties.

-

Surface Treatment:

Ordinary plane, embossing, printing and special surface effect painted steel plate (anti-scrape, suede, mesh, etc.)

Special Coating function For Prepainted Steel Coil/Sheet:

- The width range of the supplied steel plate for ANSON steel is 700-1550mm; The thickness range of the design is 0.2-2.0 mm, which can provide the steel volume of 508 or 610mm inner diameter.

- The antibacterial coating of ANSON steel can inhibit the breeding of escherichia coli, staphylococcus aureus, and green bacillus in hospitals, food factories and so on.

- ANSON steel self-cleaning series coated steel plate by increasing the crosslinking density and forming hydrophilic coating to achieve self-cleaning effect.

- The thermal insulation series of ANSON steel is reflected by the special pigments in the coating to reflect the infrared heat in the sunlight, so as to reduce the temperature of the building and save energy.

Prepainted Steel Coil Production

Prepainted Steel Coil ProductionPrepainted Steel Coil/Sheet Application:

| Construction | Outside | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

|---|---|---|

| inside | door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

| Electrial Application | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

| Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

| Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

| Other | writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

Steel Grade and Application Fields of Prepainted steel coil/sheet:

| Type of base metal | Steel grade | Grade of base metal | Application |

|---|---|---|---|

| Hot-dip zinc coated | TDC51D+Z | DC51D+Z | Normal use |

| TDC52D+Z | DC52D+Z | For drawing | |

| TDC53D+Z | DC53D+Z | For deep drawing | |

| TS280GD+Z | S280GD+Z | Structure | |

| TS350GD+Z | S350GD+Z | Structure | |

| TS550GD+Z | S550GD+Z | For high-strength structure | |

| Hot-dip alu-zinc alloy coated | TDC51D+AZ | DC51D+AZ | Normal use |

| TDC52D+AZ | DC52D+AZ | For drawing | |

| TS250GD+AZ | S250GD+AZ | Structure | |

| TS300GD+AZ | S300GD+AZ | Structure | |

| TS350GD+AZ | S350GD+AZ | Structure | |

| TS550GD+AZ | S550GD+AZ | For high-strength structure | |

| Electro-galvanized | TSECC | SECC | Normal use |

| TSECD | SECD | For drawing | |

| TSECE | SECE | For deep drawing | |

| TBLCE+Z | BLCE+Z | Normal use | |

| TBLDE+Z | BLDE+Z | For drawing | |

| TBLDE+Z | BUSDE+Z | For deep drawing |

Size Range of Prepainted steel coil/sheet:

| Items | Nominal dimensions |

|---|---|

| Nominal thickness | 0.22~2.0 |

| Nominal width | 700~1550 |

| Nominal cut length | 1000-4000 |

Plainness of cold rolled substrate, electro-galvanized substrate steel coil:

|

Yield Strength Min Mpa |

Nominal width | Common precise PF.A | High-level precision PF.B | ||||

|---|---|---|---|---|---|---|---|

| Nominal thickness | Nominal thickness | ||||||

| <0.70 | 0.7-1.20 | >1.2 | <0.70 | 0.7-1.20 | >1.2 | ||

| <260 | ≤1200 | 10 | 8 | 7 | 5 | 4 | 3 |

| >1200-1500 | 12 | 10 | 8 | 6 | 5 | 4 | |

| >1500 | 17 | 15 | 13 | 8 | 7 | 6 | |

| 260-340 | ≤1200 | 13 | 10 | 8 | 8 | 6 | 5 |

| >1200-1500 | 15 | 13 | 11 | 9 | 8 | 6 | |

| >1500 | 20 | 19 | 17 | 12 | 10 | 9 | |

Plainness of hot dip galvanized substrate steel coil:

| Yield Strength min | Nominal width | Plainness (mm) for the nominal thickness as shown below | |||||

|---|---|---|---|---|---|---|---|

| Common precise PF.A | High-level precision PF.B | ||||||

| <0.70 | 0.7-1.60 | 1.6-3.0 | <0.70 | 0.7-1.60 | 1.6-3.0 | ||

| <260 | <1200 | 10 | 8 | 8 | 5 | 4 | 3 |

| 1200-1500 | 12 | 10 | 10 | 6 | 5 | 4 | |

| >1500 | 17 | 12 | 15 | 8 | 7 | 6 | |

For steel sheet and steel strip with a specified minimum yield strength not less than 260MPa but less than 360MPa, and the grades of DC51+Z(ZF), DD51D+Z and S550GD+Z(ZF), the maximum plainness tolerance should be in conformity with the stipulations of Table A2.

| Yield Strength min | Nominal width | Plainness (mm) for the nominal thickness as shown below | |||||

|---|---|---|---|---|---|---|---|

| Common precise PF.A | High-level precision PF.B | ||||||

| <0.70 | 0.7-1.60 | 1.6-3.0 | <0.70 | 0.7-1.60 | 1.6-3.0 | ||

| 260-360 | <1200 | 13 | 10 | 10 | 8 | 6 | 5 |

| 1200-1500 | 15 | 13 | 13 | 9 | 8 | 6 | |

| >1500 | 20 | 19 | 19 | 12 | 10 | 9 | |

Plainness of hot dip Al-Zn substrate steel coil:

For steel sheet with a specified minimum yield strength less than 260MPa, the maximum plainness tolerance should be in conformity with the stipulations of Table A3.

| Yield Strength min | Nominal width | Plainness (mm) for the nominal thickness as shown below | |||||

|---|---|---|---|---|---|---|---|

| Common precise PF.A | High-level precision PF.B | ||||||

| <0.70 | 0.7-1.60 | 1.6-3.0 | <0.70 | 0.7-1.60 | 1.6-3.0 | ||

| <260 | <1200 | 13 | 10 | 10 | 8 | 6 | 5 |

| 1200-1500 | 15 | 13 | 13 | 9 | 8 | 6 | |

For steel sheet with a specified minimum yield strength not less than 260MPa, but less than 360MPa, and the grades of DX51D+AZ.S550GD+AZ, the maximum plainness tolerance should be in conformity with the stipulations of Table A4.

| Yield Strength min | Nominal width | Plainness (mm) for the nominal thickness as shown below | |||||

|---|---|---|---|---|---|---|---|

| Common precise PF.A | High-level precision PF.B | ||||||

| <0.70 | 0.7-1.60 | 1.6-3.0 | <0.70 | 0.7-1.60 | 1.6-3.0 | ||

| 260-360 | <1200 | 13 | 10 | 10 | 8 | 6 | 5 |

| 1200-1500 | 15 | 13 | 13 | 9 | 8 | 6 | |

Suggestion on slection of base metal and zinc coating weight for different application:

| No. | Applications | Base metal | Weight of galvanized layer (g/m2) |

|---|---|---|---|

| 1 | Construction external use | Hot-dip zinc coated base metal | 90/90 |

| 2 | Construction internal use Steel Windows | Hot-dip zinc coated base metal | 90/90 |

| Electro-galvanized base metal | 60/60 | ||

| 3 | Household appliance、Furniture | Electro-galvanized base metal | 20/20 |

| 4 | Construction | Hot-dip zinc-aluminum coated board | 75/75 |

Mechanical Properties of cold rolled substrate and electro-galvanized substrate steel coil:

| Grade | Tensile test | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Yield strength MPa < |

Tensile strength > |

Elongation (Lo=50mm, b=25mm) % min | Nominal thickness mm | ||||||||

| Nominal thickness mm | |||||||||||

| <0.25 | 0.25-0.30 | 0.30-0.40 | 0.40-0.60 | 0.60-1.0 | 1.0-1.6- | >1.6 | 1.5-1.0 | 1.0-1.6 | |||

| SPCC | - | 270 | 25 | 28 | 31 | 34 | 36 | 37 | 38 | - | - |

| SPCD | 240 | 270 | 27 | 30 | 33 | 36 | 38 | 39 | 40 | - | - |

| SPCE | 220 | 270 | 29 | 32 | 35 | 38 | 40 | 41 | 42 | - | - |

| SPCF(SPCEN) | 210 | 270 | - | - | 37 | 40 | 42 | 43 | 44 | - | - |

| SPCG | 190 | 270 | - | - | - | 42 | 44 | 45 | 46 | 1.4 | 1.3 |

Mechanical Properties of steel sheet and steel strip should be in conformity with the stipulations of Table 16.

| Grade | Tensile test | Rmin | N min | |||||

|---|---|---|---|---|---|---|---|---|

|

Yield strength MPa max |

Tensile strength MPa min |

Elongation (Lo=50mm, b=25mm) % min | ||||||

| Nominal thickness mm | ||||||||

| <0.6 | 0.6-1.0 | 1.0-1.6 | >1.6 | |||||

| BLC | 140-270 | 270 | 36 | 38 | 40 | 42 | - | - |

| BLD | 120-240 | 270 | 38 | 40 | 42 | 44 | 1.5 | 0.18 |

| BUSD | 120-210 | 260 | 40 | 42 | 44 | 46 | 1.7 | 0.20 |

| BUFD | 120-190 | 250 | 42 | 44 | 46 | 48 | 2.0 | 0.21 |

| BSUFD | 110-180 | 250 | 44 | 46 | 48 | 50 | 2.2 | 0.22 |

Mechanical Properties of hot dip galvanized substrate steel coil:

| Grade | Tensile test | R> | N> | ||

|---|---|---|---|---|---|

|

Yield strength MPa |

Tensile strength MPa |

Elongation min | |||

| DC51D+Z, DC51D+ZF | - | 270-500 | 22 | - | - |

| DD51D+Z | - | 270-500 | - | - | - |

| DC52D+Z, DC52D+ZF | 140-300 | 270-420 | 26 | - | - |

| DC53D+Z, DC53D+ZF | 140-260 | 270-380 | 30 | - | - |

| DC54D+Z | 120-220 | 260-350 | 36 | 1.6 | 0.18 |

| DC54D+ZF | 34 | 1.4 | 0.18 | ||

| DD54D+Z | <260 | <360 | 36 | - | - |

| DC56D+Z | 120-180 | 260-350 | 39 | 1.9 | 0.21 |

| DC56D+ZF | 37 | 1.7 | 0.20 | ||

| DC57D+Z | 120-170 | 260-350 | 41 | 2.1 | 0.22 |

| DC57D+ZF | 39 | 1.9 | 0.21 | ||

| Grade | Tensile test | ||

|---|---|---|---|

|

Yield strength MPa max |

Tensile strength MPa min |

Tensile strength MPa min |

|

| S220GD+Z, S220GD+ZF | 220 | 300 | 20 |

| S250GD+Z, S250GD+ZF | 250 | 330 | 19 |

| S280GD+Z, S280GD+ZF | 280 | 360 | 18 |

| S320GD+Z, S320GD+ZF | 320 | 390 | 17 |

| S350GD+Z, S350GD+ZF | 350 | 420 | 16 |

| S550GD+Z | 550 | 550 | - |

Mechanical properties of hot dip Al-Zn substrate steel coil:

| Grade | Tensile test | ||

|---|---|---|---|

|

Yield strength MPa |

Tensile strength MPa |

Elongation | |

| DC51D+AZ | - | 270-500 | 22 |

| DC52D+AZ | 140-300 | 270-420 | 26 |

| DC53D+AZ | 140-260 | 270-380 | 30 |

| DC54D+AZ | 120-220 | 260-350 | 36 |

Common performance of front coating of prepainted steel coil/sheet:

| Category | Thickness(μm) |

Pencil hardness |

60° specular glossiness of coating | 180°bend | Impact (J) |

saltfog resistant (h) |

|||

|---|---|---|---|---|---|---|---|---|---|

| Low | Moderate | High | (thickness of steel materials for door and window ≤0.80mm | ||||||

| A level | B level | ||||||||

| PE | ≥20 | ≥F | <40 | 40~70 | >70 | ≤5T | ≤3T | ≥9 | ≥500 |

| SMP | ≥20 | ≥F | <40 | 40~70 | >70 | ≤5T | ≤3T | ≥9 | |

| HDP | ≥20 | ≥HB | <40 | 40~70 | - | ≤5T | ≤3T | ≥9 | ≥1000 |

| PVDF | ≥20 | ≥HB | <40 | 40~70 | - | ≤5T | ≤3T | ≥9 | ≥1000 |

Performance Comparison for Different Back Coating Structures (Controlling Value)

| Coating structure | 2/1 | 2/1M | 2/2 |

|---|---|---|---|

| Coating layer | 1 | 2 | 2 |

| Color | Yellow-green | Steel white | Cloud white |

| Coating thickness | 5-7μm | 8-10μm | 13-18μm |

| Glossiness | - | 30-50 | 40-60 |

| Pencil hardness | F-2H | ≥F | F-2H |

| Reverse Impact | ≥9J | ≥9J | ≥9J |

| Flexibility | ≤3T | ≤3T | ≤3T |

| Application | Sandwich sheet | Sandwich sheet, Single layer panel | Single layer panel |