Introduction of API 5L X52 Specification:

API 5L standard is the core specification for oil and gas pipelines, and its strategic importance lies in ensuring the safe and efficient operation of the global energy artery.

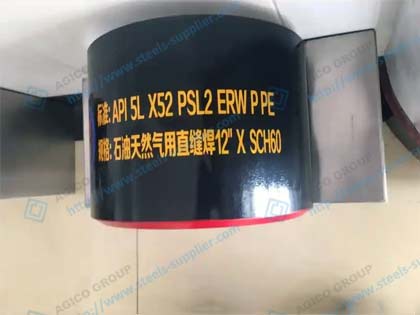

API 5L X52 PSL2 ERW Pipe

API 5L X52 PSL2 ERW PipeAmong them, X52 grade line pipe has become the dominant force in medium- and high-strength pipeline steel, it has an excellent balance of strength and toughness and its cost-effective. It is widely used in land and sea transportation systems and supports modern energy infrastructure.

What is Api 5l Grade X52

X52N SSAW Pipe

X52N SSAW Pipe X52M Seamless Pipe

X52M Seamless Pipe X52 QS Seamless Pipe

X52 QS Seamless Pipe- Basic Definition: X52 meaning: "X" represents the minimum yield strength in ksi, "52" means 52,000 psi (≈360 MPa), and the metric code is L360.

- Core Advantage: Achieves a critical balance between reliability and cost to meet most medium- and high-voltage transmission scenarios.

Key Differences Of API 5L PSL1 and PSL2 Grading

Same as other API 5L Line Pipe Grades, API 5L Grade X52 pipe can also be seperated into psl1 and psl2 levels, their main differences are as follow:

- PSL1 (Basic Level): Focuses on essential chemical composition and mechanical properties (tensile strength, hardness), with relatively relaxed requirements, suitable for non-harsh environments.

-

PSL2 (Enhanced Level): Features significantly increased requirements, including:

- Stricter control of chemical composition (especially S, P impurities)

- Mandatory Charpy V-notch impact toughness tests

- More comprehensive non-destructive testing (UT/AUT, RT)

- Higher elongation requirements

- Application scenarios: high-consequence areas, low-temperature environments, submarine pipelines, and important urban pipeline networks.

Special X52 Grade Description:

In steel classes of psl1 and psl2, steel mills from China has also developed X52M for metric system, and X52N for normal pressure working conditions.

- X52M: Pure metric version, with the same technical requirements as X52, suitable for use in projects following the metric system.

- X52N PSL2: Optimized for normal pressure service environments (such as some underwater pipelines and non-high-pressure onshore pipelines), with slight adjustments to chemical composition or certain performance requirements to meet specific service conditions.

X52 PSL1 and PSL2 Mechanical and Chemical Properties

Mechanical Properties Comparasion - X52 PSL1 VS PSL2 - (at room temperature)

| Performance parameters | PSL1 Requirements | PSL2 Requirements | Metric Equivalent (approximate) | |

|---|---|---|---|---|

| Yield strength (Rp0.5) | ≥ 52,000 psi | ≥ 52,000 psi | ≥ 360 MPa | |

| Tensile strength (Rm) | ≥ 66,000 psi | ≥ 66,000 psi | ≥ 455 MPa | |

| Elongation(A) | ≥ 21% (gauge length 8 inches) | ≥ 23% (gauge length 8 inches) |

Low temperature toughness requirements (PSL2 exclusive)

- Test standard: Charpy V-notch impact test (CVN).

- Test temperature: 0°C (32°F).

- Minimum absorbed energy: The specific requirements depend on the pipe diameter and wall thickness (please refer to the standard table), which aims to ensure that the pipe can resist brittle fracture at the expected minimum service temperature.

Chemical composition control range

Basic element limits of X52 psl1 and psl2, psl2 has strict element limitation for higher purity and mechanical property (typical, please check the standard for details) :

| Element | Control Range | Remarks |

|---|---|---|

| Carbon (C) | PSL2 ≤ 0.22% | PSL1 limit is slightly looser |

| Manganese (Mn) | 0.90% - 1.60% | Important strengthening element, PSL2 may have upper limit control |

| Phosphorus (P) | PSL2 ≤ 0.025% | Strictly controlled harmful element to improve purity and toughness |

| Sulfur (S) | PSL2 ≤ 0.015% | Strictly controlled harmful element to improve purity and toughness |

| Microalloying Elements (Nb, V, Ti) | Small amounts | Improve strength and toughness through fine grain and precipitation strengthening |

Dimensional Specifications of API 5L X52 From AGICO

Since AGICO has multiple source of large steel mills in China, we can supply almost the full range of dimensions of API 5L X52 as line pipes.

| Category | Description |

|---|---|

| Outside Diameter (OD) | Extremely wide range, from Ø21.3mm (small diameter instrument tube) to Ø1420mm (large diameter main line) |

| Wall Thickness (WT) | According to ASME B36.10 standard, covering SCH 20 (Std) to XXS (extra thick) to meet various pressure level needs |

| Specification Capabilities | API 5L X52 seamless and welded pipes are available in full size range |

API 5L X52 Line Pipe Types and Features:

| Process Type | Representative Process | Main Features | Typical Applications |

|---|---|---|---|

| Seamless pipe (SMLS) | Hot rolled/cold drawn | Uniform structure, no weld weakness ; high pressure bearing capacity; high dimensional accuracy; high cost | High-pressure gathering and transportation, harsh environment, key pipe fittings |

| Welded pipe | ERW (High Frequency Longitudinal Welding) | High efficiency, low cost; continuous improvement in weld quality; wide range of sizes | Long-distance land transportation trunk lines, urban pipeline networks, and structural pipes |

| LSAW (Longitudinal Submerged Arc Welding)/UOE | Main force for large diameter thick wall pipes; excellent weld quality; large size capacity (Ø>24”) | Trunk lines, submarine pipelines | |

| SSAW (Spiral Submerged Arc Welding) | Flexible production of large diameter pipes; relatively complex residual stress; high cost performance | Large-diameter low-pressure transmission pipes and pipe piles |

Material Equivalent Steel Standards of API 5L X52:

EN10208 Seamless Pipe

EN10208 Seamless PipeInternational EN Standard Equivalence

-

EN 10208:

- L360NB: Corresponds to API 5L X52 PSL1 (mainly seamless pipes).

- L360MB: Corresponds to API 5L X52 PSL2 (mainly welded pipes).

- ISO 3183: L360 grade directly matches API 5L X52/L360, with highly consistent standard requirements.

ASTM A106 Grade B Pipe

ASTM A106 Grade B PipeAPI 5L X52 Equivalent ASTM Standards:

- ASTM A106 Gr.B: Seamless carbon steel pipe mainly used for high-temperature services (such as power station boiler tubes). Its strength is close to X52, but the standard emphasizes different aspects (not dedicated to pipelines).

- ASTM A53 Gr.B: General-purpose carbon steel pipe standard (seamless/welded), with strength grade equivalent to X52 PSL1 (B grade yield ≥35ksi). However, its chemical composition and toughness requirements are usually lower than API 5L PSL2, and it is commonly used for low-pressure fluid transportation and structural support.

- ASTM A333 Gr.6: A seamless welded pipe specifically designed for low-temperature toughness requirements, with strength close to X52. Its main value lies in its excellent -45°C impact performance, used in cryogenic environments.

Purchase Guide of API 5L X52 Line Pipe

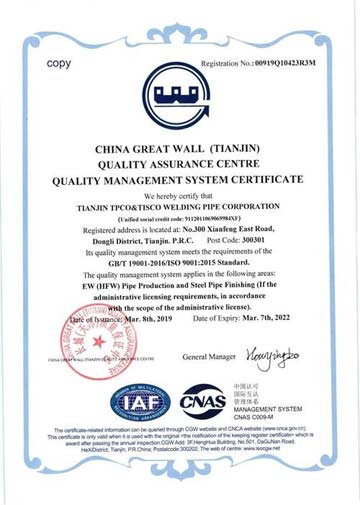

Welded Pipe Quality Management Certification

Welded Pipe Quality Management CertificationAGICO shows you how to find the best API 5L X52 line pipe Supplier:

- Mandatory Certification: Manufacturers with a valid API Monogram license are preferred. This is the core credential for quality assurance. Checking the API official website for a list of authorized manufacturers is essential.

-

Regional Representative Manufacturers:

- China: Baosteel, Ansteel, Tianjin Pipe (TPCO) - the main players in global production capacity and exports.

- Europe: Tenaris, ArcelorMittal.

- Japan and South Korea: JFE Steel, Nippon Steel, POSCO - known for their high value-added products.

Which one to choose PSL1 or PSL2:

When customer make the order, the basic requirement of API 5L X52 shall be clear: PSL1 or PSL2? This is the critical distinction between cost and performance and must be clearly stated in the order, customer can also request a certificate of compliance:

- PSL1: At minimum, a Type 2.2 Material Test Certificate (MTC) by ISO 10474 / EN 10204 is required.

- PSL2: A Type 3.1 or 3.2 MTC, including all mandatory test results (chemical composition, mechanical properties, impact, NDT), must be provided.

- Anti-corrosion Support Requirements: Clarify coating standards (such as ISO 21809 FBE/3LPE) to ensure compatibility of the steel pipe factory production with the coating process. Consider protection requirements for transportation and storage.

API 5L X52 Line Pipe Typical Applications

- Onshore Gathering and Transportation Pipeline Network: The main artery connecting the wellhead to the processing plant, capable of withstanding medium and high pressures. PSL2 level X52 is the main choice to ensure safe passage through complex terrains.

- Subsea Secondary Pressure System: X52N PSL2 is often used for oil flow pipes and jumper pipes in non-deepwater areas to balance performance with cost.

- City Gas Medium-Pressure Distribution Network: To distribute natural gas to end users, ERW X52 (PSL1/PSL2) is widely used because of its economy and reliability.