API 5L X46 Pipe – Seamless & Welded Line Pipe Supplier

API 5L X46 is a medium-strength carbon steel pipe grade utilized in pipeline transportation systems for petroleum, natural gas, and water. Although it is not as frequently used as higher grades like X52 or X60, X46 remains a reliable option for certain low-to-medium pressure projects and legacy systems. API 5L X46M Welded Pipe

API 5L X46M Welded Pipe API 5L X46 Seamless Pipe

API 5L X46 Seamless PipeAGICO offers a detailed overview of X46 pipe specifications, customers can check it’s chemical and mechanical properties, delivery states, etc, and reasons why it is not listed among mainstream pipeline steel grades.

Why API 5L X46 Is Less Common in the Market

API 5L X46 is a recognized grade under the API 5L standard, but it is not less frequenctly used than other steel grades’ products. For pipes with higher-strength materials has been developed for replacement.

Here are the reasons why API 5L X46 is not a mainstream steel grade:

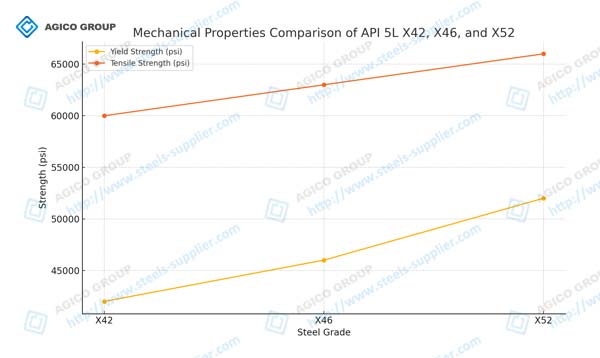

- It provides moderate strength, now engineers can choose X52 or higher grades for better performance margins.

- It’s tensile strength is between X42 and X52, but most procurement requires to jump directly to X52 for versatility.

- Not all steel mills produce X46, so it is not easy for customers to find it when needed.

- Demand is usually limited to small and costless projects or existing pipeline systems maintenance built with X46 pipe.

Because of this, X46 remains relevant in specific environments and can be supplied whenever you'd like.

API 5L X46 Specification Overview

The API 5L standard encompasses seamless and welded steel line pipes. X46 is part of the Grade X series, with a specified minimum yield strength of 46,000 psi. It is produced to meet the requirements of PSL1 or PSL2 levels.

API 5L X46 NH

API 5L X46 NH API 5L X46 NO

API 5L X46 NO API 5L X46N

API 5L X46N API 5L X46 NS

API 5L X46 NS API 5L X46 QH

API 5L X46 QH API 5L X46 NS

API 5L X46 NSThe following table outlines the basic product parameters for API 5L X46 pipes:

| Grade | Type | Wall Thickness | OD Range | Length | PSL Level |

|---|---|---|---|---|---|

| X46 | Seamless/Welded | SCH 10 to 160 | 1/2" – 48" | 6m – 12m | PSL1 / PSL2 |

Available X46 Pipe Forms

API 5L X46 pipes are offered at AGICO in various forms and manufacturing types, making them adaptable to specific project needs. Seamless pipe and welded pipes: ERW (Electric Resistance Welded) Pipe, LSAW and SSAW (Submerged Arc Welded) Pipe.

Here are the pipe coating options and pipe end forms:

- Manufacturing Methods: Seamless, ERW, LSAW, SSAW

- Standards: API 5L, ISO 3183, EN10208, ASME B36.10M

- Pipe Ends: Plain End, Beveled End, or Threaded

- Surface Options: Black paint, varnish, 3LPE, FBE coating

Chemical Composition of API 5L X46

API 5L X46 pipes are manufactured with carefully controlled chemical compositions to achieve the required strength and weldability. PSL2 imposes stricter chemical limits and may include micro-alloying elements such as Nb, V, or Ti.

Chemical Composition for X46 PSL 1 pipe

| Steel Grade | Mass fraction, % based on heat and product analyses a,g | ||||||

|---|---|---|---|---|---|---|---|

| C | Mn | P | S | V | Nb | Ti | |

| max b | max b | max | max | max | max | max | |

| Seamless Pipe | |||||||

| X46 | 0.28 | 1.4 | 0.3 | 0.3 | d | d | d |

| Welded Pipe | |||||||

| X46 | 0.26 | 1.4 | 0.3 | 0.3 | d | d | d |

|

b. For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70., d. Nb + V + TI ≤ 0.15%, |

|||||||

Chemical Composition for X46 PSL 2 pipe

| Steel Grade | Mass fraction, % based on heat and product analyses | Carbon Equiv a | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | V | Nb | Ti | Other | CE IIW | CE Pcm | |||||||||

| max b | max | max b | max | max | max | max | max | max | max | ||||||||||

| Seamless and Welded Pipe | |||||||||||||||||||

| X46N | 0.24 | 0.4 | 1.4 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | d,e,l | 0.43 | 0.25 | ||||||||

| X46Q | 0.18 | 0.45 | 1.4 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||

| Welded Pipe | |||||||||||||||||||

| X46M | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | e,l | 0.43 | 0.25 | ||||||||

|

b. For each reduction of 0.01% below the specified maximum for C, an increase of 0.05% above the specified maximum for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; up to a maximum of 2.00% for grades ≥ L485 or X70, but ≤ L555 or X80; and up to a maximum of 2.20% for grades > L555 or X80., d. Nb = V = Ti ≤ 0.15%, e. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% and Mo ≤ 0.15%, l. For all PSL 2 pipe grades except those grades with footnotes j noted, the following applies. Unless otherwise agreed no intentional addition of B is permitted and residual B ≤ 0.001%. |

|||||||||||||||||||

Mechanical Properties of API 5L X46 Pipe

API 5L X46 delivers moderate yield and tensile strength, suitable for lower-pressure and short-distance applications. PSL2 pipes undergo additional testing and stricter mechanical property requirements.

Refer to the table below for detailed mechanical characteristics:

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 1 | Seam of Welded Pipe | ||

|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Elongation | Tensile Strength b | |

| Rt0,5 PSI Min | Rm PSI Min | (in 2in Af % min) | Rm PSI Min | |

| X46 | 46,400 | 63,100 | c | 63,100 |

| a. For intermediate grade, the difference between the specified minimum tensile strength and the specified minimum yield for the pipe body shall be as given for the next higher grade. | ||||

| b. For the intermediate grades, the specified minimum tensile strength for the weld seam shall be the same as determined for the body using foot note a. | ||||

| c. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation: | ||||

| Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units | ||||

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 2 | Seam of Welded Pipe | |||||

|---|---|---|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Ratio a,c | Elongation | Tensile Strength d | |||

| Rt0,5 PSI Min | Rm PSI Min | R10,5IRm | (in 2in)Af % | Rm (psi) | |||

| Minimum | Maximum | Minimum | Maximum | Maximum | Minimum | Minimum | |

| X46N,X46Q,X46M | 46,400 | 76,100 | 63,100 | 95,000 | 0.93 | f | 63,100 |

| a. For intermediate grade, refer to the full API5L specification. | |||||||

| b. for grades > X90 refer to the full API5L specification. | |||||||

| c. This limit applies for pies with D> 12.750 in | |||||||

| d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using foot a. | |||||||

| f. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation: | |||||||

|

|

|||||||

| Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units | |||||||

Delivery Status

| Grade | Allowed status | Disabled state | According to the terms |

|---|---|---|---|

| PSL1 | Hot rolling, normalizing | Quenching + tempering | API 5L 6.1.3 |

| PSL2 | Normalizing (N), Thermomechanical Rolling (M) | Hot Rolling | Mandatory requirements |

Typical Applications

Although x46 pipe has limited use in mainstream of oil and gas transmission, API 5L X46 still finds application in certain fields. It is often selected for small- to medium-sized pipelines or where legacy systems are designed for X46. It can also be used in the high-pressure applications: pressure vessels, heat exchangers, etc.

Common uses include:

- Low-pressure oil and gas pipelines

- Water transport systems

- Onshore pipeline networks

- Existing systems with X46 pipe installations

| Case | Reasons for selection | Alternative Risk |

|---|---|---|

| Texas crude oil old pipeline network repair (1958) | Welding compatibility matches the original pipe | Replacing X52 may cause weld failure |

| Kenya irrigation pipes | The cost of hot rolled pipe is 5% lower than X52 | PE pipe life is insufficient |

Gurranteed Pipe Quality - Documentation and Testing

To ensure the quality of X46 pipe and realize compliance and traceability, all X46 pipes are supplied to customers with full documentation and inspection reports.

AGICO provide:

- Mill Test Certificates (EN 10204 3.1/3.2)

- NDT and impact test reports (for PSL2)

- Third-party inspection reports (SGS, BV, DNV, etc.)

- Custom markings, packing lists, invoices, and origin certificates

Why Choose AGICO for API 5L X46 Pipe

As a proven global supplier, AGICO has been delivering API 5L X46 pipes tailored to various projects needs, including non-standard grades or small-volume orders.

One stop services from AGICO:

- Reliable sourcing of rare grades like X46

- Fast delivery of stocked sizes

- Flexible minimum order quantities for trials or projects

- Export services to over 40 countries

- Responsive support for EPC contractors and project engineers

Frequently Asked Questions OF API 5L X46

Q1: Why would someone choose X46 over X42 or X52?

A: X46 offers a balance between strength and cost. It’s ideal when X42 is too weak and X52 is unnecessarily strong for the application.

Q2: Can you supply X46 for sour service?

A: Yes, PSL2 X46 pipe can be certified for sour service if produced according to NACE MR0175 standards.

Q3: Is X46 pipe available for custom orders?

A: Yes, we can source or produce custom sizes, coatings, and lengths upon request.

Q4: What’s the minimum order quantity?

A: We accept small trial orders, typically starting from five tons or one lot 20-foot container.

X46 PSL1 vs PSL2: What's the Difference?

AGICO supplies x42 pipes in 2 classes: psl1 and psl2, buy line pipes in suitable grade can benefit customers both in the purchasing and maintenance in the long run of the project. AGICO engineers can help customer to choose based on the operating conditions of the application, especially if sour service or traceability is required.

Here are the 4 key differences in the x46 psl1 and psl2 production process:

- Chemical Composition: PSL2 has higher controls on carbon, phosphorus, and sulfur.

- Testing Requirements: PSL2 requires non-destructive testing (NDT) and Charpy impact testing.

- Traceability: PSL2 must maintain full material traceability from plate to pipe.

- Sour Service Suitability: PSL2 can meet NACE MR0175 standards for H2S environments.