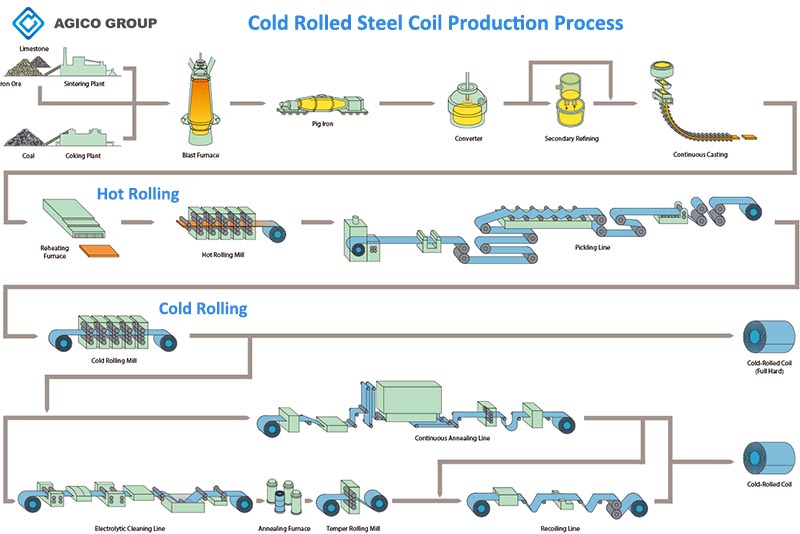

Hot Rolling Process for Steel Coil

Hot rolling uses slabs (mainly continuous slabs) as raw materials, and after heating, strips are made from rough rolling mills and finishing mills. The hot strip from the last rolling stand of the finish rolling is cooled by laminar flow to the set temperature. It is coiled by a coiler into a steel coil and the coiled steel is subjected to different finishing operations according to the user's different requirements. Lines (leveling, straightening, crosscutting or slitting, inspection, weighing, packaging, marking, etc.) are processed into steel plates, flat rolled and slit strips. To put it simply, a piece of slab is heated after it has been heated (that is, the hot, red hot steel piece on TV), rolled, and trimmed to form a steel plate.

Common Hot Rolled Steel Coil Grades

Cold Rolling Process for Steel Coil

Cold rolling: Using hot-rolled steel coils as raw materials, oxidizing the hides and removing the scales and then performing tandem cold rolling. The finished products are rolled hard rolls. The cold work hardening due to continuous cold deformation makes the strength, hardness, and toughness of the rolled hard rolls rise. The plastic index drops, so the stamping performance will deteriorate, and it can only be used for simple deformed parts. Rolled hard coils can be used as raw materials for hot dip galvanizing plants because hot dip galvanizing units are all provided with annealing lines. The weight of the rolled hard coil is generally 6~13.5 tons. The coil is continuously rolled at room temperature under the normal temperature. The inner diameter is 610mm.

Cold Rolled Coil Product features:

Because it has not been annealed, its hardness is very high (HRB is greater than 90), and its machining performance is extremely poor. It can only perform simple directional bending processing (with a direction perpendicular to the take-up direction) of less than 90 degrees.Commen Cold Rolled Coil Grades:

- JIS G3141-SPCC-SD, SPCC-SB, SPCD-SD, SPEC-SD

- JIS G3135-SPFC 340/390/440

- EN10130-DC01, DC03, DC04

- SAE1006, SAE1008

- ASTM A424-TypeⅡ

Cold Rolling-Deep Processing of Hot Rolling

To put it simply, cold rolling is performed on the basis of hot-rolled coils. Generally speaking, it is hot-rolling, pickling, and cold-rolling.

Cold rolling is performed at a normal temperature by hot-rolled sheet. Although the steel sheet is heated during rolling, it is still called cold-rolled. Due to cold rolling after continuous hot rolling, the mechanical properties are poor and the hardness is too high. It must be annealed to restore its mechanical properties. No annealing is called rolled hard rolls. Rolled hard rolls are generally used to make products that do not need to be bent or stretched, and have a hardness of 1.0 or less. Hard rolled luck is good on both sides or on four sides. AGICO supplies cold rolled steel coil and sheet product for worldwide customers, if you are interested contact us now!